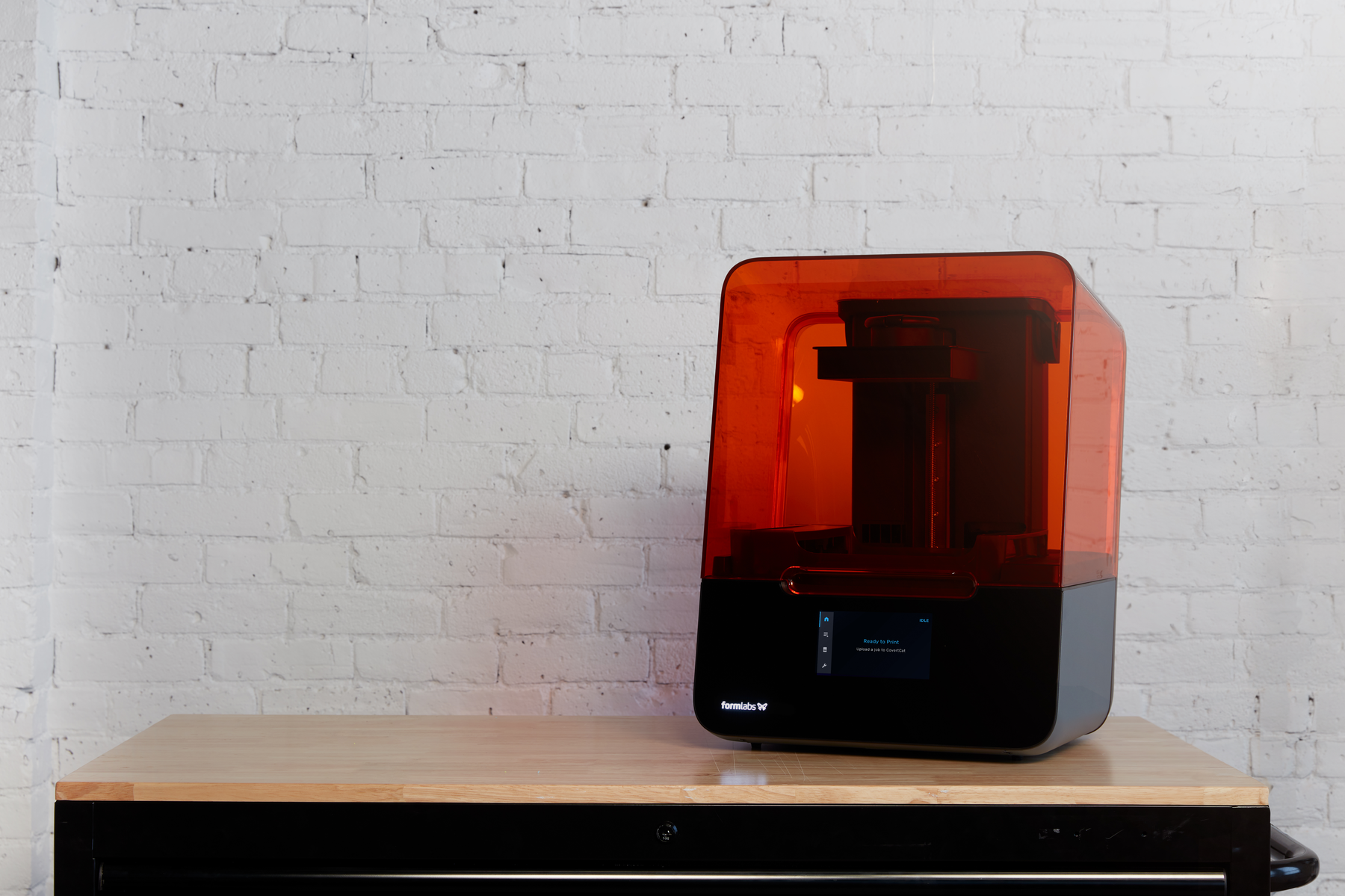

Form 3 3D Printer

The Form 3 from industry pioneers Formlabs gives users who are prototyping and making small parts industrial capabilities at a fraction of the price of other machines. This has helped numerous organisations with bringing production in-house with little specialised training required.

Form 3

Key Features

- 250mW laser with a resolution of 25 microns delivers precise control, so you can produce repeatable parts with the minimum of fuss

- A flexible tank reduces forces while printing, allowing for fewer supports to be used in your part or prototype

- Easy to operate with a high resolution, 5.5-inch touchscreen

- Change materials in seconds with the straightforward cartridge system

- Sensors automatically monitor the print process and adjust it for you to maintain the accuracy of your part

- Easy to maintain with replacement parts done on-site (if needed), removing the need to ship the printer back to base

Over 20 materials available

Choose from a large library of over 20 materials that are being added to all the time – if you can imagine it, the Form 3 can print it. With an incredible selection of engineering resins, such as rigid, flexible, elastic and high temperature, plus a lot more to choose from besides, you are spoiled for choice.

Work how you want

Use Formlabs’ simple PreForm software to prepare and send your CAD file to the machine using Wi-Fi. Then use the built-in, high-resolution touchscreen to manage your job queue. The Form Wash and Form Cure post-processing machines are available as optional extras to make the rinsing and curing of your parts easier and more automated.

Pinpoint Precision

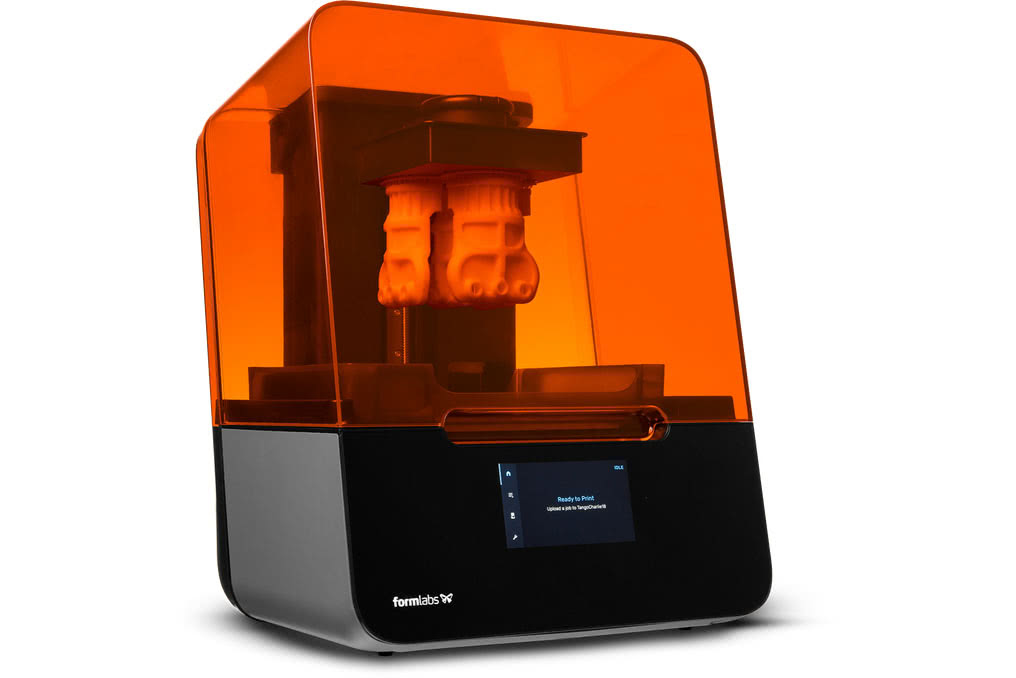

The custom-designed Light Processing Unit (LPU) inside the printer uses a compact system of lenses and mirrors to deliver accurate, repeatable prints.

Nonstop Printing

The Form 3 constantly monitors print performance so you can focus on bringing your most creative ideas to life. Integrated sensors help maintain ideal print conditions and send you alerts about the state of your machine.

Grows With Your Business

Start with one 3D printer or many, and add capacity as demand grows. Use the same tool through prototyping and into production and easily expand into new applications.

Low Force Stereolithography

The Formlabs Form 3 uses re-engineered printing technology for its best-ever print performance – all in a remarkably compact system. Known as Low Force Stereolithography (LFS), the process reduces forces for consistent printing producing the smoothest finish yet, and with fewer supports needed to complete your project. Users get fast, accurate repeatable prints every time, from a unique Light Processing Unit. This uses a powerful laser combined with a parabolic mirror and spatial filter whose optical sensors continuously correct orientation to maintain ideal print conditions. Laser Lines provides the Form 3 as a complete package, with everything you need to get started including a resin tank, build platform, finish kit and Formlabs’ excellent PreForm software – providing hassle-free materials management.

Form 3 Workflow in Five Minutes

Form 3 is a part of a robust 3D printing suite that takes little effort and requires no maintenance. The high-power density laser is passed in spatial filters to maintain a clean target. An intelligent sensor system keeps an optimal printer running and can send you alerts about the status of your printer. With improvements in layer resolution and surface finishing in light-based substrates, translucent materials print faster than ever on the printer. The laser prints perpendicular to the build plane while ensuring uniform print quality across the entire build platform.

Grows with your business

Formlabs 3D printers work instantly when installed, with no specialised training needed. The Form 3 provides industrial capabilities for a fraction of the price of traditional industrial machines. The only things which are not cross-compatible are the resin tanks purely because each resin has its own dedicated tank. If you are upgrading your Form 2 you will be thrilled to know that your cartridges, build platforms, Form Wash and Form Cure will work perfectly with Form 3.