Description

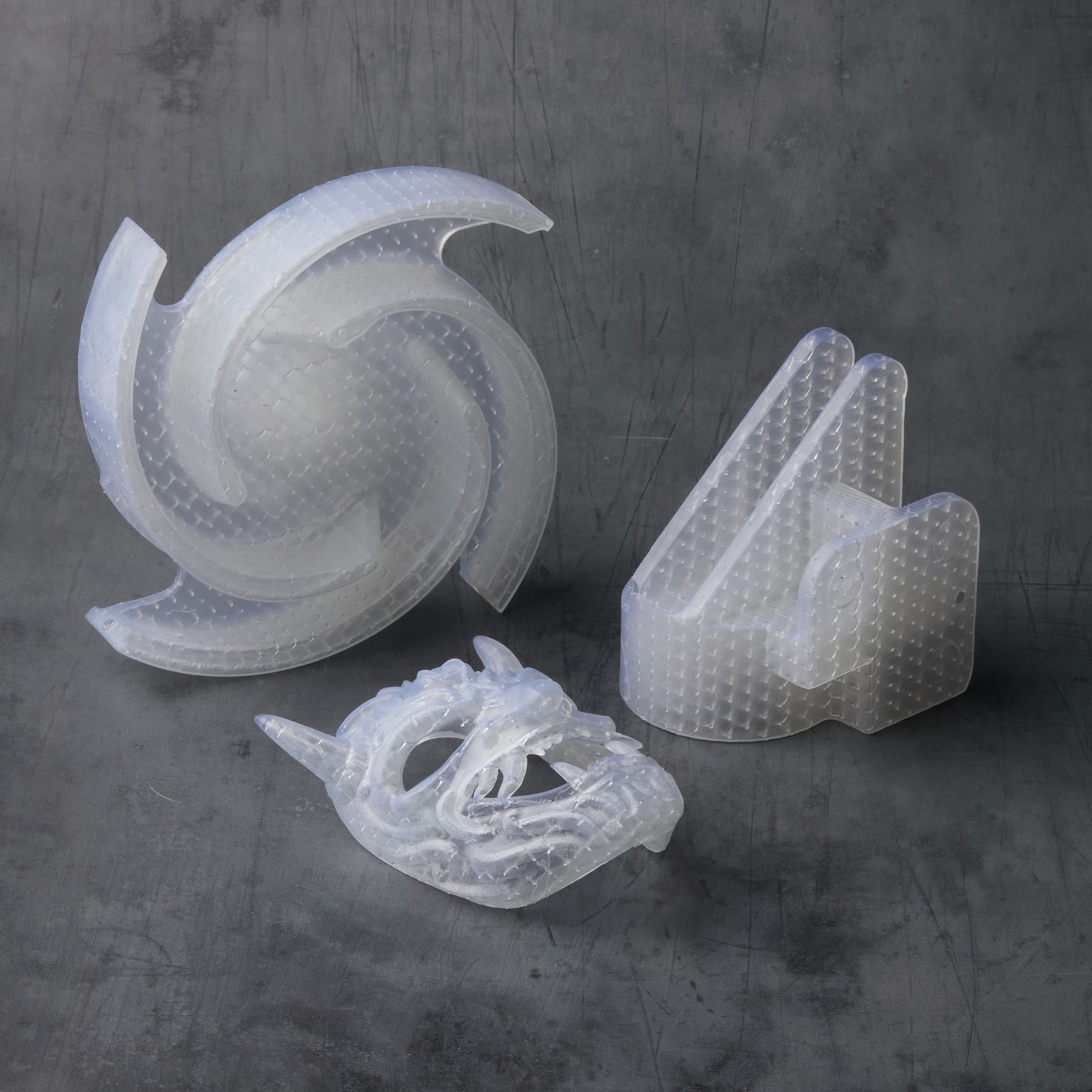

Clear Cast Resin is a resin designed for investment casting, to directly print patterns that can be invested and cast. It has an extremely low thermal expansion, low ash, and no trace heavy metals. Clear Cast Resin, paired with a latticing software, is recommended for use with larger parts, excelling at producing geometries thicker than 3 mm.

Reducing Lead Time and Cost With 3D Printed Patterns 3D printing the sacrificial pattern has emerged as a cost and time-effective alternative to wax mould creation, enabling faster turnaround times and competitive prices. Because it eliminates tooling, SLA 3D printing allows patterns to be in hand the next day. It requires very limited equipment, freeing up CNC capacity and skilled operators’ time for other high-value tasks. Rapid tooling with 3D printing is already used in common manufacturing processes to iterate quickly, accelerate product development, and bring better products to market. Manufacturers are also 3D printing short-run moulds with polymeric 3D printing for low-volume wax and plastic injection moulding. 3 FORMLABS: Fuse Series SLS Design Guide Stereolithography (SLA) 3D printing technology is a great choice for mould and pattern making. It is characterized by a smooth surface finish and high precision that the tool will transfer to the final part, producing surface finishes similar to the wax it replaces. SLA 3D printing also offers unmatched design freedom to create complex and intricate patterns. The Formlabs SLA ecosystem and Clear Cast Resin provide an accessible and reliable solution for pattern making. The Form 3L enables large-scale printing with a 33.5 x 20 x 30 cm build volume, while the Form 4 is an excellent solution to produce smaller parts (20 x 12.5 x 21 cm) at high speed. Formlabs SLA 3D printers can integrate seamlessly into any workflow as they are easy to implement, operate, and maintain. Clear Cast Resin is an antimony-free material with low ash content (<0.02%), manufactured in the US, and has shown the ability to achieve dimensional accuracy, surface quality, and cost-per-part requirements for a wide range of applications.